Introduction to Hydraulic Presses: How These Industrial Machines Are Revolutionizing Modern Manufacturing

A hydraulic press is a powerful machine that uses fluid pressure to generate compressive force. At its core, it operates on Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic presses to apply immense force through small inputs, making them indispensable in manufacturing, metal forming, molding, and more.

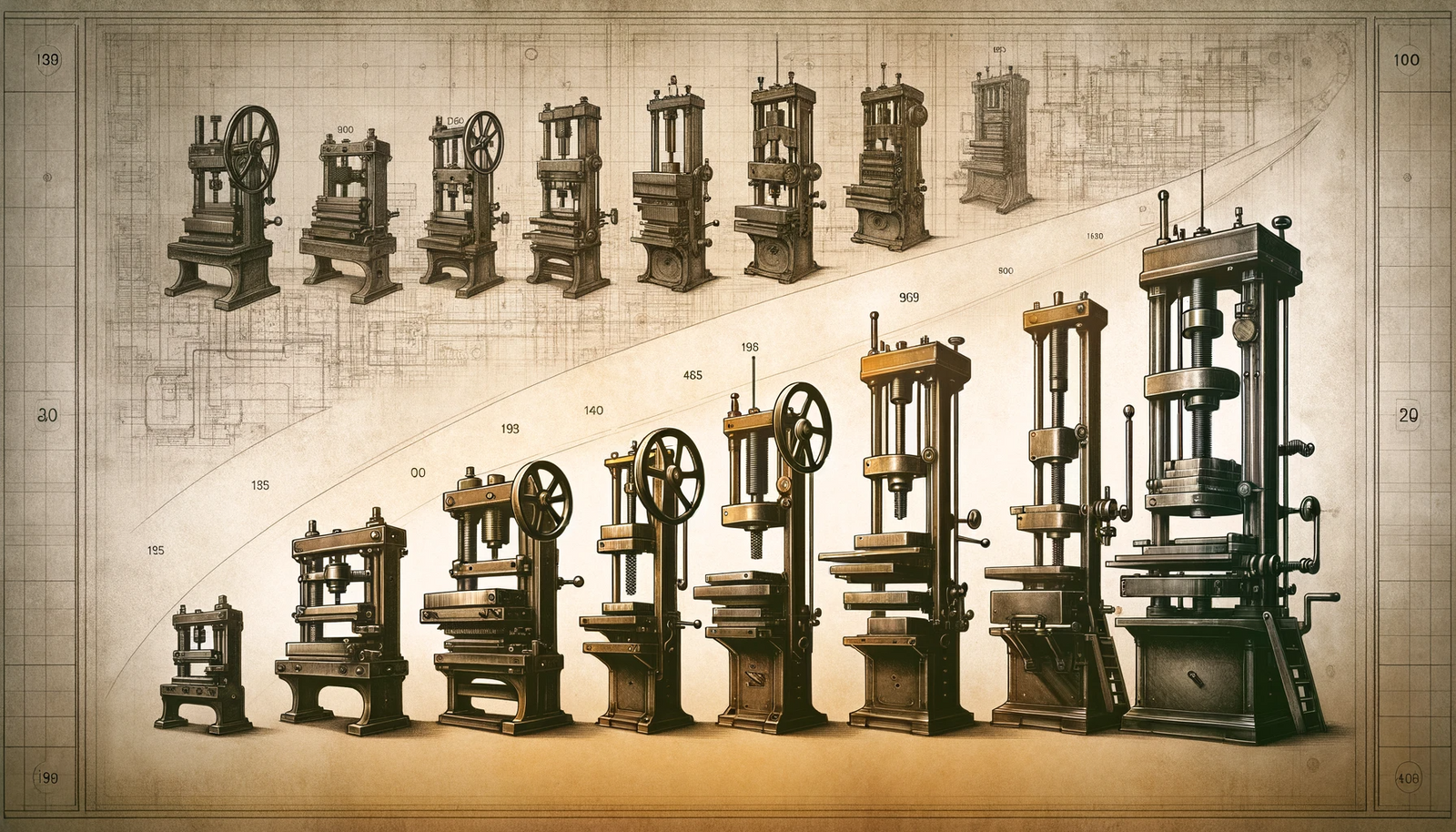

Hydraulic presses have evolved over the decades from simple manual machines to highly advanced, computer-controlled systems used in everything from automotive assembly lines to electronics production. The ability to shape, cut, compress, and mold materials with great precision has made these machines vital across multiple industries.

Why Hydraulic Presses Matter in Today’s World

1. A Pillar in Modern Manufacturing

Hydraulic presses play a critical role in mass production. They are used in forming metal car body panels, plastic components, composite parts, rubber products, and even medical devices. Their efficiency allows for consistent output, reduced material waste, and uniform quality.

2. Industries Impacted

-

Automotive: For pressing parts such as hoods, fenders, and chassis components.

-

Aerospace: Used to form high-strength aluminum and titanium components.

-

Electronics: Involved in circuit board lamination and part forming.

-

Plastic Manufacturing: Utilized in injection molding and thermoforming.

-

Construction: For creating support beams, tiles, and prefabricated structures.

3. Problem-Solving Capabilities

Hydraulic presses address various production challenges:

-

Labor Reduction: Automation and reduced manual input.

-

Precision Control: Customizable force and pressure settings.

-

Scalability: Easy adaptation for small or large-scale operations.

-

Versatility: Can handle various materials—metal, plastic, rubber, and composites.

Recent Trends and Developments (2024–2025)

In the past year, hydraulic press technology has seen several innovations, reflecting broader trends in manufacturing automation and sustainability:

1. Integration with Smart Technologies

-

IoT-enabled hydraulic presses now monitor pressure, temperature, and cycle data in real time, improving operational efficiency.

-

Predictive Maintenance Systems are reducing downtime by identifying wear and tear before failure occurs.

2. Energy-Efficient Models

Eco-conscious hydraulic presses, introduced in late 2024, feature variable displacement pumps and servo motors that lower energy consumption by up to 60% compared to traditional models.

3. Compact & Modular Designs

Manufacturers like Schuler and Enerpac introduced modular presses in early 2025. These models allow easier customization and transport, particularly useful for SMEs and workshops with space constraints.

4. Increased Use in Green Manufacturing

Presses are being used in recycled material processing, particularly for compressed wood, metal recycling, and bioplastics, aligning with circular economy principles.

| Feature | Traditional Press | 2025 Smart Press |

|---|---|---|

| Energy Efficiency | Low | High |

| Maintenance | Manual | Predictive |

| Space Requirement | Large | Compact/Modular |

| Monitoring | Limited | IoT-Based |

| Cost Efficiency | Medium | High (Long-Term) |

Regulations and Policies Impacting Hydraulic Press Use

Regulatory compliance is essential for operating hydraulic presses safely and sustainably. Here are some key guidelines from various governing bodies:

1. Safety Standards

-

OSHA (Occupational Safety and Health Administration - USA) mandates proper guarding, two-hand trip controls, and emergency stops.

-

CE Certification (EU) ensures machines meet environmental and safety directives.

-

ISO 16092-2:2019 governs the safety of hydraulic presses worldwide.

2. Environmental Regulations

-

The EU Ecodesign Directive (2024 update) encourages the use of energy-efficient industrial machinery.

-

EPA (U.S. Environmental Protection Agency) requires proper disposal of hydraulic fluids and mandates leak detection systems.

3. Industry-Specific Guidelines

In aerospace and medical manufacturing, hydraulic presses must adhere to traceability and cleanroom compliance, such as those dictated by AS9100 and ISO 13485 standards.

4. Government Programs & Incentives

-

In India, under the Production Linked Incentive (PLI) scheme, manufacturers upgrading to energy-efficient or smart machines, including hydraulic presses, may receive capital subsidies.

-

In Germany and Japan, government grants are available for digitally retrofitting traditional machinery with Industry 4.0 components.

Helpful Tools and Resources for Users and Engineers

Whether you're a manufacturer, engineer, or student, these resources can support deeper learning or application of hydraulic press technology:

1. Simulation and Design Tools

-

ANSYS Mechanical: For press system simulations and stress analysis.

-

SolidWorks Motion Study: Helps simulate the motion and force of press parts.

-

Hydraulic Press Force Calculator (available online): Allows quick estimation of force based on cylinder diameter and pressure.

2. Training Platforms

-

SME Tooling U: Offers training courses in press operations and safety.

-

Coursera/edX: Hosts mechanical engineering and automation courses.

-

YouTube Channels like "Engineer’s Academy" provide visual breakdowns of hydraulic system mechanisms.

3. Industry Standards and References

-

SAE International: Standards for automotive-related press operations.

-

ISO Standards Catalog: Technical requirements for hydraulic equipment.

4. Software Solutions

-

SCADA Systems (like Ignition or Wonderware): Real-time press monitoring and automation.

-

ERP Integration Tools: For linking press output to supply chain or inventory systems.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between a hydraulic press and a mechanical press?

A: A mechanical press uses flywheel energy and mechanical linkages, making it suitable for fast, repetitive operations. Hydraulic presses, on the other hand, use fluid pressure, allowing for more force control and handling of complex, slower tasks.

Q2: How much force can a hydraulic press generate?

A: It depends on the design, but industrial hydraulic presses can range from 10 tons to over 10,000 tons. The required force depends on the material, size, and desired shape.

Q3: Are hydraulic presses dangerous to operate?

A: Like any heavy machinery, they can be hazardous without proper safety measures. However, modern hydraulic presses include guarding, sensors, and emergency shut-offs, making them safer when operated according to standards like OSHA or ISO.

Q4: Can a hydraulic press be used for materials other than metal?

A: Yes. Hydraulic presses are versatile and can handle plastic, rubber, composites, wood, ceramics, and even biomaterials for various industries.

Q5: How long does a hydraulic press typically last?

A: With proper maintenance, a hydraulic press can last 15 to 30 years. Modern smart features like predictive maintenance extend lifespan by reducing wear-related failures.

Conclusion

Hydraulic presses have become essential tools in shaping the future of modern manufacturing. From high-precision applications to large-scale production, these machines offer power, versatility, and control. With the integration of smart technologies and stricter environmental and safety standards, the role of hydraulic presses is only set to grow. By staying informed about recent innovations, compliance guidelines, and helpful tools, industries can leverage hydraulic press technology to enhance productivity, reduce waste, and meet evolving market demands.

Whether you're in automotive engineering, electronics, or plastic manufacturing, understanding how hydraulic presses function—and how they’re evolving—can provide a valuable edge in today’s competitive industrial landscape.